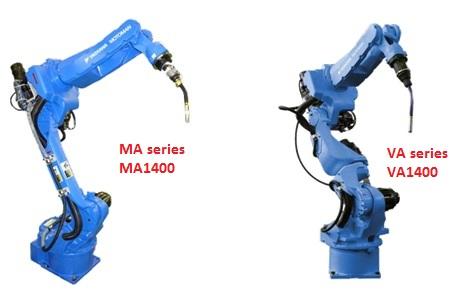

Arc Welding Robots

Arc Welding Series 17668 views

YASKAWA, a leader in arc welding provides revolutionary "short processing".

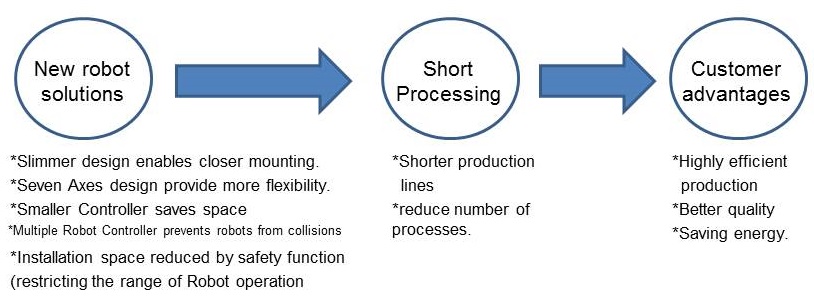

"Short Processing"

Increase freedom in operation or compact and slim design have made the new robots more optimized for specific applications. High-density installation has contributed customer production line saving space. The facility which enables integrated process, rapid production and saving space is called "short processing".

Save Space and Energy

Structures, performance and functions designed for optimum application help you to downsize production facilities and save energy.

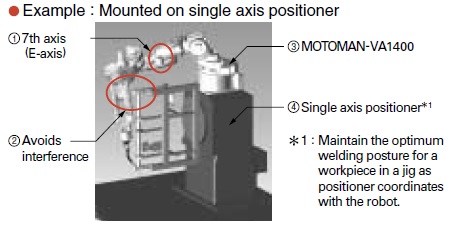

Easily avoid interference

With the 7th axis (E-axis), the arm can easily avoid interference with workpieces and jigs as well as keep the optimal torch posture by going around to the back of workpeices. Large workpievces can be handled and welding can be done the workpiece.

Use 50% less space with high density layout

With the robot on shelf or on the top of the positioner, welding can start from the top of the workpiece, and the installation space can be halved. If the robots are in close proximity, the arms can be easilty posed to avaoid intereference, and several robots can be placed in small space.

Increase operability and maintainability with built-in cables

Not only are the torch cables inside the U-arm, but the welding earth cable as well as the gas and air hoses are inside the base. This reduces the space in which the cables can move and stretches the cable's life.

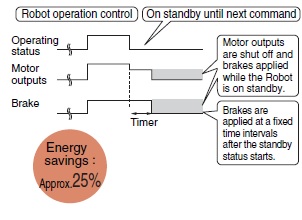

Reduced power consumption helps lower running costs.

The servos are turned OFF automatically when the Robot is stopped for long period of time.

Twenty four hour operation in which Robot is operating for 16 hours and on stand by for 8 hours

High Productivity and Quality

Faster and higher quality arc welding with wide variety of functions reduces wasted motion and cycle times.

Quicker Welding

The welding time per head can be reduced by starting the next motion while checking to make sure no wire sticking occured at the end of the arc welding process.

Settings for Welding Functions

Improve welding quality by defining the preflow and postflow of the gas as well as the slope (transition) when setting the conditions for the start and the end of arc welding.

Shift Function on Coordinate Sytem (optional)

Simplify teaching by using numerical values to adjust or shift the target position and attain high-quality welding.

Torch Angle Display (optional)

Teaching operation becomes easier by viewing the torch angel on the programming pendant.

Easy Operation and Simulation

Operability of teaching and simulation have been improved to reduce time required for system startup.

Operated highly skilled technique by programming pendant

•Multi-window display - improve efficiency by checking the programmed motion with the I/O data and variables displayed during teaching or trial operations. When an alarm occurs, the type of errors, its cause and suggested remedy are displayed.

•Arc Monitoring(optional) - Can easily check the welding results with a graphic display of the welding current and voltage.